Analysis of the Influence of Indian Cookware (J4) on Household Induction Cooker

Feb 20,2021

In the past year or two, many customers engaged in the production/sales of household induction cookers have provided feedback. For household induction cookers sold in India, after a few months of use, the percentage of abnormal quality of the entire appliance is much higher than in other sales regions. The problem of abnormal quality of the whole machine is mainly concentrated in high temperature protection, (fuse/rectifier bridge/IGBT/filter capacitor/resonant capacitor) burnout, etc. According to the analysis results provided by several customers, the main problem lies in supporting the use of pots and pans. India mainly uses J4 flower pots, while other regions mainly use 430/304 flower pots.

The company's 5μF filter capacitor and 0.3μF resonant capacitor have been adopted by many customers. We have also collected that the failure rate of complete machines sold in India is much higher than the overall failure rate. In view of this, the company also analyzed the cause of the capacitor failure on its own and worked out a series of improvement measures in cooperation with customers. After many times of cooperation and rectification with many customers, we can basically solve the problems that need to be paid attention to when using film capacitors in India. Specific conditions are as follows:

One: Analysis of the causes of film capacitor heating

The ideal film capacitor is a purely capacitive electronic component. As long as the capacitor is charged, electrical energy may be permanently stored in the capacitor. But in fact, due to the structure, material and production process and other factors, the film capacitor will have a certain stray inductance (ESL), equivalent series resistance (ESR), parallel resistance, etc., which will cause the film capacitor to generate heat. The film capacitor itself is lost. The formula for calculating the heat loss of a film capacitor is P (heating) = 2 * Pi * F * C * U * U * tg θ From this formula, we can know that the heating of a film capacitor follows the frequency F passing the operating voltage U across the capacitor, and the operating voltage U across the capacitor. The capacitance C of the capacitor itself is proportional to the loss tangent of the capacitor. The larger these parameters are, the more the capacitor itself heats up.

For filter capacitors, the most important factors affecting their heating are ripple voltage and ripple current.The ripple voltage is usually only 30-50Vpp, and high-order ripples exist in the range of 100Hz to 1MHZ or more, with complex waveforms and rich frequencies. At present, there is no reliable calculation formula and measurement method for calculating ripple current.

Two: household induction cooker using India J4 cooker on the electrical performance parameters of the whole machine:

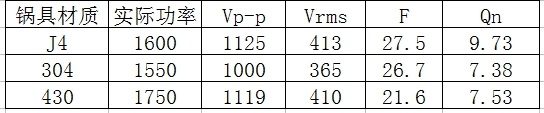

The 2000W model sold to India by a company of the same induction cooker was replaced by different pots 430, 304,J4, and the measured voltage waveform data of the 0.33μF resonant capacitor actually working are as follows:

It can be seen from the above data that when J4 cookware is used on the same machine, the Qn (reactive power) of the resonant capacitor is the largest, which is nearly 30% higher than the other two cookware. Qn is the reactive power that the resonant capacitor needs to carry when operating.

Three: India J4 cooker on the impact of household induction cooker

According to the measured data, the actual working resonance frequency of the domestic induction cooker will increase when using the Indian J4 cooker. After the resonance frequency increases, it will have a certain impact on the electronic components inside the machine, such as the temperature rise of PCB copper foil, rectifier bridge, choke coil, filter capacitor, resonance capacitor, IGBT, coil disc, etc. Increase, in severe cases, an explosion will occur.

For a resonant capacitor, the resonant frequency increases, and the reactive power that the capacitor needs to withstand will increase, causing the resonant capacitor to heat itself, which is reflected in the temperature increase of the resonant capacitor. For the filter capacitor, the resonance frequency increases, the ripple voltage generated by the IGBT due to high-speed switching will increase, the number of high-order ripples will increase, and the ripple current flowing through the filter capacitor will increase, which is finally reflected in the temperature rise of the filter capacitor. High.

4: Advice on domestic induction cookers for sale to India

A. Improve the electrical performance margin of key components and materials, such as rectifier bridges, filter capacitors, resonant capacitors, coil boards, IGBTs, heat sinks, fans and PCB copper foil.For example, the current value is increased and the heat dissipation condition is improved.

B. Adjust the chip control scheme of the whole machine to suppress the abnormal temperature rise of key components by limiting the power. For example, when it is detected that the pot is made of J4 and other materials, the power supply and temperature rise protection are set on the software.

Five: the improvement direction of filter capacitor and resonant capacitor

Household induction cookers sold in India are used with J4 cookware. If there is no change in the software control, only the heat generated by the filter capacitor and the resonance capacitor can be reduced, thereby reducing the temperature rise of the capacitor.

For filter capacitors, there are several ways to improve:

A increases the capacity of the filter capacitor. (increase from 5 μF to 6 μF,7 μF,8 μF, etc.)

B Because the size of the fourth-generation small-capacity capacitor is relatively small, the carrying capacity of the spray gold end face of the capacitor seems to be somewhat insufficient when used in harsh electrical parameters and environments, so it is recommended to change it to the third-generation large-capacity capacitor.

C The most ideal effect is to adopt the third-generation large-volume structure, keep the capacity of the filter capacitor unchanged, and shorten the pitch of the capacitor (from P = 30.5MM to P = 26.5MM). This can shorten the width of the film and increase winding. Increase the area of the spray gold end face to reduce the self-heating of the filter capacitor.

For resonant capacitors, there are the following directions for improvement:

Answer: Since the fourth-generation small-capacity capacitors are relatively small, and when used in harsh electrical parameters and environments, the carrying capacity of the sprayed gold end faces of the capacitors seems to be slightly insufficient, it is recommended to change them to the third-generation large-capacity capacitors.

The most ideal effect of B is to adopt the third generation large volume structure, keep the capacity of the filter capacitor unchanged, and shorten the pitch of the capacitor (from P = 30.5MM to P = 26.5MM). This can shorten the width of the film and increase winding. Increase the area of the gold-sprayed end face to reduce the self-heating of the resonant capacitor.

C may consider appropriately increasing the capacitance of the resonant capacitor and appropriately adjusting the reel parameters to lower the LC resonant frequency, thereby reducing the temperature rise of the associated electronic components as a whole, and ultimately ensuring reliable use.

Through the improvement and test evaluation of the film capacitor solutions of many customers, the above solutions can solve the problems of high temperature and burning of filter capacitors and resonant capacitors when used in a complete set of household induction cookers in India. Since each company's home induction cooker scheme and structural cooperation are different, the actual installation evaluation will eventually need to be finalized.

Other News